Key Benefits

- A recyclable film made partly from recycled polyethylene

- Recycled raw material originates partly from a closed loop process

- Provides compressed protection for your sawn timber

- Available with an integrated and recyclable friction surface for safe storage

- Available with high-quality, wide flexo-printing

Effective protection in all weather conditions

Our ready-made timber hoods, converted from our high-performance timber film, offer effective protection for your sawn timber products. The film contains the same technical features as our timber film and protects your timber products against dust, sun damage and moisture.

Our timber hoods can be supplied with your company logo or other graphics for improved brand visibility. We use the latest flexo-printing technology available on the market.

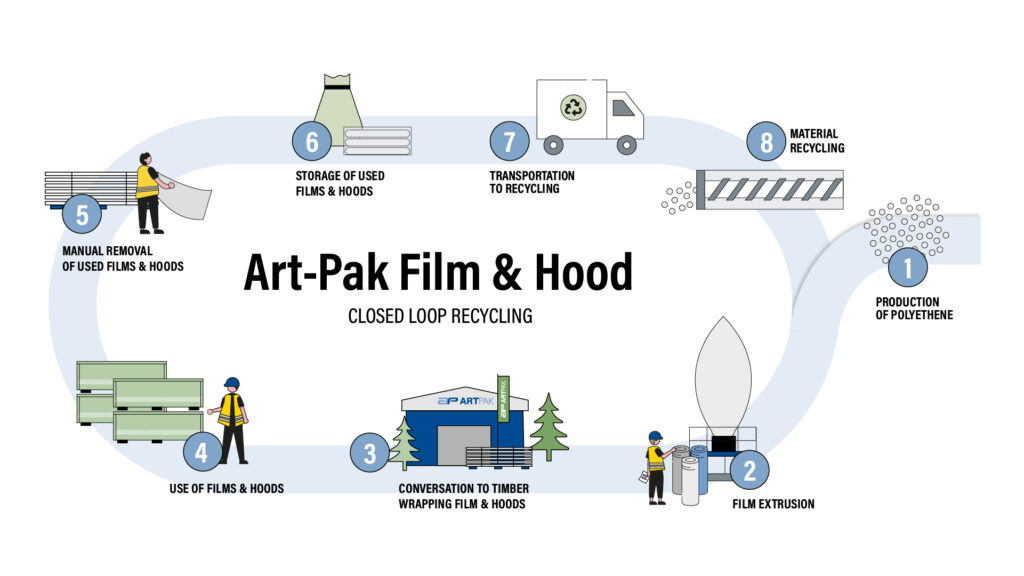

If you are looking for a sustainability advantage, you might consider using our ready-made timber wrapping hoods, which require less plastic film in the packaging process. Like our timber wrapping films, our timber wrapping hoods contain high percentages of recycled raw material, which partly originates from a closed loop recycling process, where used timber wrapping become new timber wrapping.

Product versions

You can find timber wrapping hoods of different sizes and dimensions in our assortment, depending on your packaging needs.

Sustainable packaging

Through our ongoing product development, we have taken several measures to ensure our films and production processes are sustainable. Our films are now thinner and stronger, while maintaining all their required technical properties. We continue to increase the amount of renewable and recycled raw material used in our films whenever it is technically possible and is of benefit to the customer. We continuously optimise our printing process to make it more efficient, safer, and greener. Our aim is to help our customers find the best solutions to meet their sustainable packaging challenges.